Today, hydraulic pipe fittings have become a necessity in several industries worldwide. Because of their capability to control the passage of fluid in pipes, these are rather important, more so in commercial as well as industrial uses. In this article, you will learn what hydraulic pipe fittings are, why they are so crucial, and why they have recently started trending.

What does hydraulic pipe fitting involve

The major work of hydraulic pipe fitting is that of regulation of release of liquid at high pressure like oil or water in specific. Such fittings are crucial in that they make sure that pipes are well connected in a way that the fluid is to flow through the required pipe without hindrances such as leakage.

Why Popular Hydraulic Pipe Fittings

For the last couple of years, hydraulic pipe fittings have had their market demand in various industrial segments. Let’s see some reason for their popularity:

- Versatility: The hydraulic pipe fittings are applied in various systems and equipment in construction equipment manufacturing tools amongst others.

- Durability: Since hydraulic pipe fittings are an engineering product, hence they are robust, which signifies that they can bear heavy pressure and several other adverse conditions. In unfavourable working conditions, they may work for long in a way that might consider them for replacement, thereby cutting costs.

- Enhanced Efficiency: It may be important to note that in the presence of proper fittings, hydraulic systems can work effectively, which can make the flow of the said hydraulic systems better. Precisely, it enhances the efficiency of industries that apply such systems, and hence the productivity increases.

Some of the types of hydraulic pipe fittings

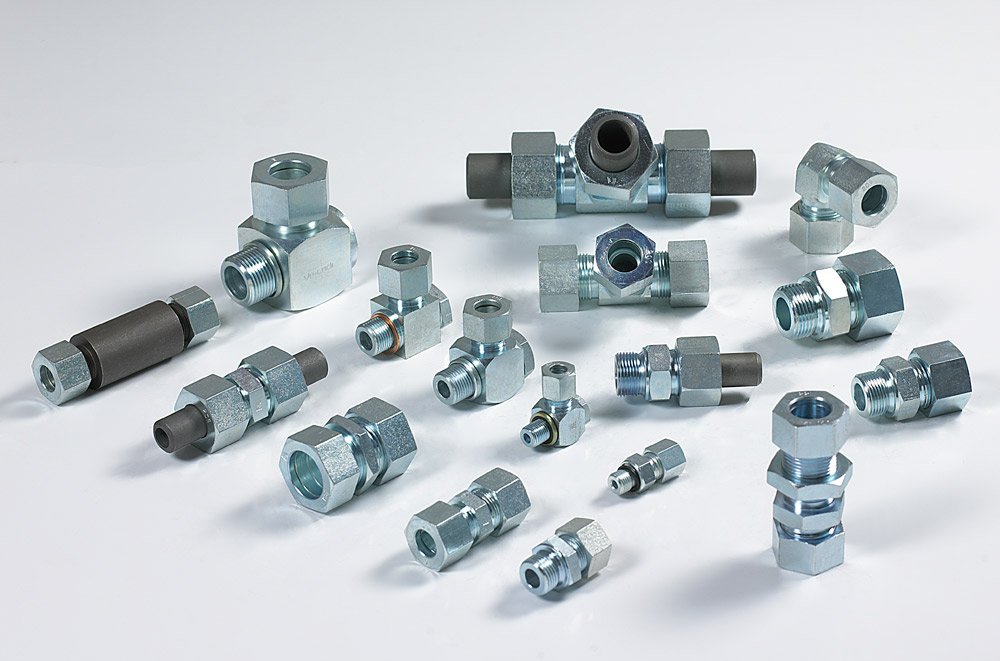

The hydraulic pipe fittings mentioned come in several forms. Some of the most common include:

- Elbow Fittings: Elbow fittings particularly are utilized to solve this problem since they help to change the flow direction in any hydraulic system. It is used most of the time in the form of 45 to degrees or is formed when reaching a 90 degrees angle.

- Tee Fittings: Tee fittings are among those in the system that are supposed to split the direction of the flow in two opposite directions or be instrumental in joining two flows in one. These fittings are normally ‘T’ shaped as the very term indicates to anyone interested in these products.

- Coupling Fittings: Those applications where one pipe or hose has to be connected to another pipe or hose calls for couplings. These changes may be permanent or temporary depending on whether the need that has been imposed on them is permanent or temporary respectively.

The Role Played by Hydraulic Pipe Fittings in Diverse Sectors

- Agriculture: Many of the farming tools applied in farming have extensive hydraulic operation; this includes tractors and harvesters. They also let the movement control of different parts in other to conduct activities like plowing sowing and reaping.

- Manufacturing: Almost all manufacturing processes, including pressing, molding, lifting, and so on, include hydraulic systems within their process. Hydraulic pipe fittings are involved in these processes since they are them in flow control in a manner that would protect flow for use in machinery.

- Automotive: Hydraulic systems in the car industry are implemented in the braking and steering mechanisms. As with all these systems, piping requires the use of good and sound pipe fittings which need to be effective in performance and safe.

Hydraulic Pipe Fittings: The Future

Hydraulic pipe fittings are still gaining enhancement due to the developments in the technology that forms them and stand to be a good shot for being suited to new uses. Therefore, to adapt to these changes in the industries and the specificity of application, as well as to deal with the pressures and efficiency that increase with time, there have to be improvements in the materials used for fittings. This is most probably what will occur to make the need for defining the requirements of the future in terms of materials and designs or manufacturing processes.

Selection of the appropriate hydraulic pipe fittings

Hydraulic pipe fittings are very sensitive; hence a lot of caution needs to be taken while selecting the right ones to be used in the system. Some key factors to consider when choosing fittings include:

- Material: Fittings include steel, stainless steel, and brass as some of the materials used in the development of such products. The material to be used will thereby depend on aspects such as the environment in which the fittings are to be used as well as the fluid to be managed.

- Size: Fittings have to be of the correct sizes to make certain that leakage is not a problem. The name of the pipes or hoses that are to be connected will be identified and will assist in establishing the size that would be required.

- Type of Connection: The type of connection that will be required in the form of interconnectivity will always differ depending on the system that is being used. The wiring connections may include threaded connectors sometimes than compression or flange connectors in other cases.

By understanding the above factors, they should be able to come up with this decision which will enable industries to choose the right fittings for hydraulic systems to prevent future complications.

Conclusion:

As has been discussed, hydraulic pipe fittings are viewed to be extremely crucial in industries and markets in today’s world. This has been due to general attributes such as flexibility, wear resistance, and the ability to improve the productivity of specific usages. These fittings which are produced and utilized in the construction of pumps, motors, and other associations aid the hydraulic system to operate efficiently and securely.

Other than hydraulic pipe fittings, there are butt weld pipe fittings which are also common in several industries. These fittings make certain to have strong and tight compiled pipes, especially the ones that are used the several pressurized systems and high-temperature systems. Owing to the continued demand for quality and long-lasting pipe systems, hydraulic pipe fittings, and buttweld pipe fittings are likely to feature greatly in the future demands of industrial usage.